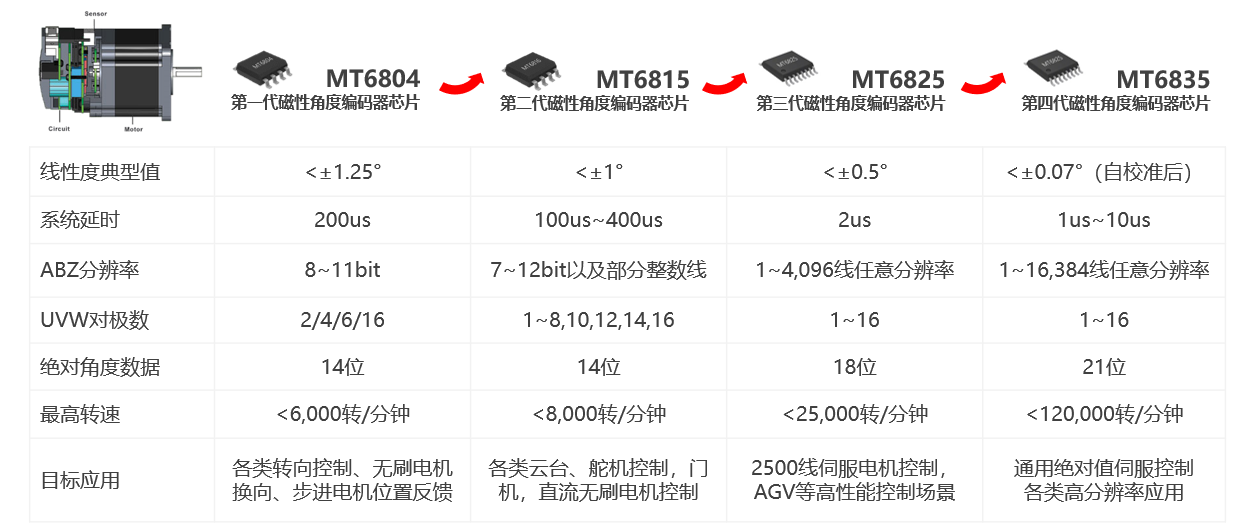

MT6835 chip is the fourth generation magnetic angle encoder IC newly launched by MagnTek, which is a new upgraded chip of MT6825. It is based on anisotropic magnetoresistive (AMR) technology and proprietary signal processing technology to achieve absolute angle measurement of 0 °~360 °.

The chip consists of a pair of AMR Wheatstone bridges and signal processing ASIC circuits. With the rotation of the magnetic field parallel to the chip surface, the chip can output angle signals such as ABZ/UVW, PWM, etc. At the same time, users can read the 21 bit absolute angle data inside the chip through the SPI interface that supports up to 16MHz clocks. Support up to 120000 rpm. MT6835 chip can be used in various application scenarios with high-speed and high-precision control requirements, such as closed-loop stepping motor control, servo applications of 2500 lines to 16384 lines, and 17 bit absolute value servo motor applications.

| Core improvement

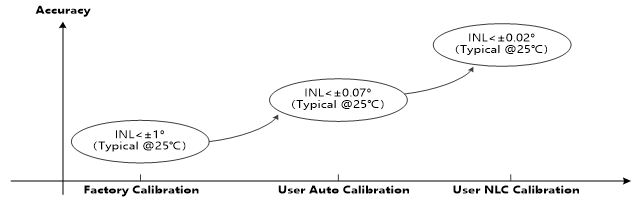

INL

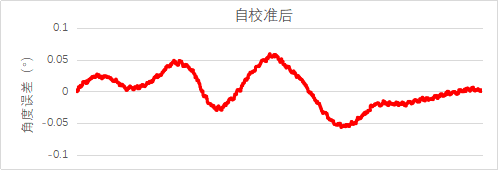

The MT6835 provides a client self calibration mode. In this mode, the system only needs to operate at a constant speed without any data interaction. The MT6835 chip will automatically calculate and calibrate all kinds of non-linearity caused by magnets, installation position deviations and the chip itself, and automatically store them in the built-in EEPROM of the chip. After uniform self calibration, the INL can be reduced to within ± 0.07 ° (typ.). In addition, MT6835 also provides a further NLC drag calibration mode, which can reduce the INL to within ± 0.02 ° (typical value).

| Closed loop speed fluctuation

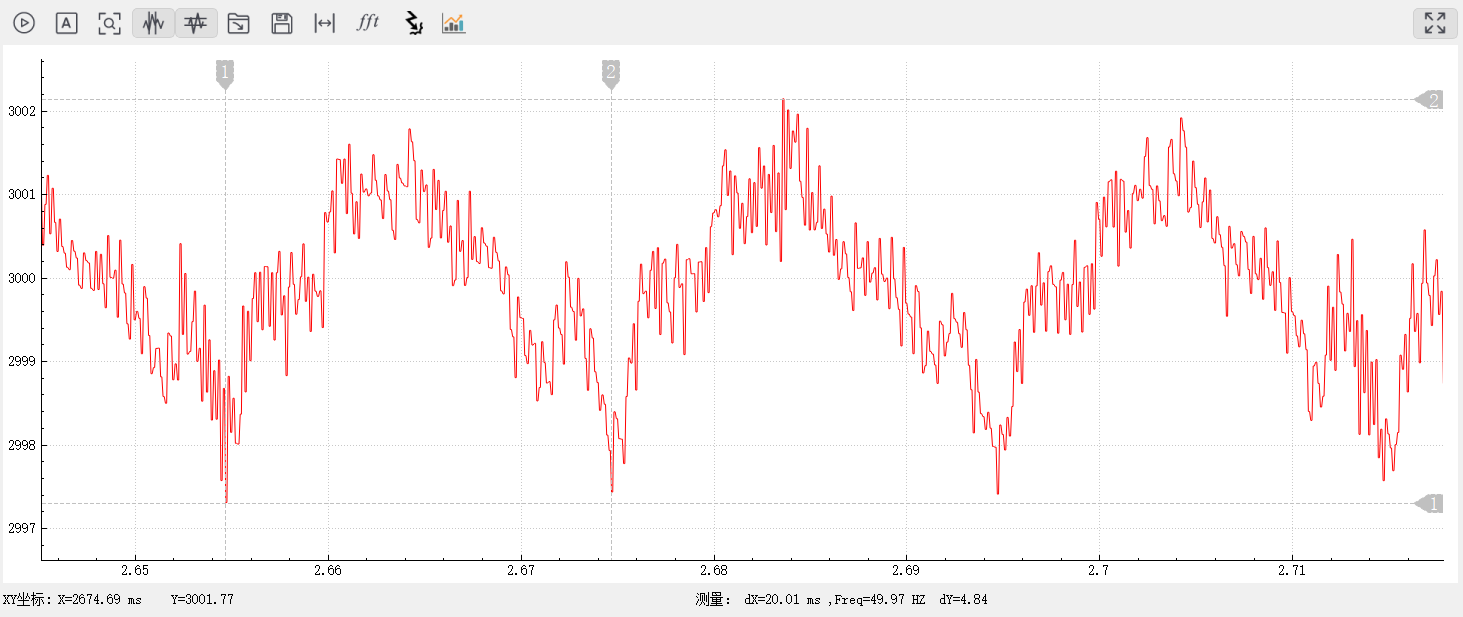

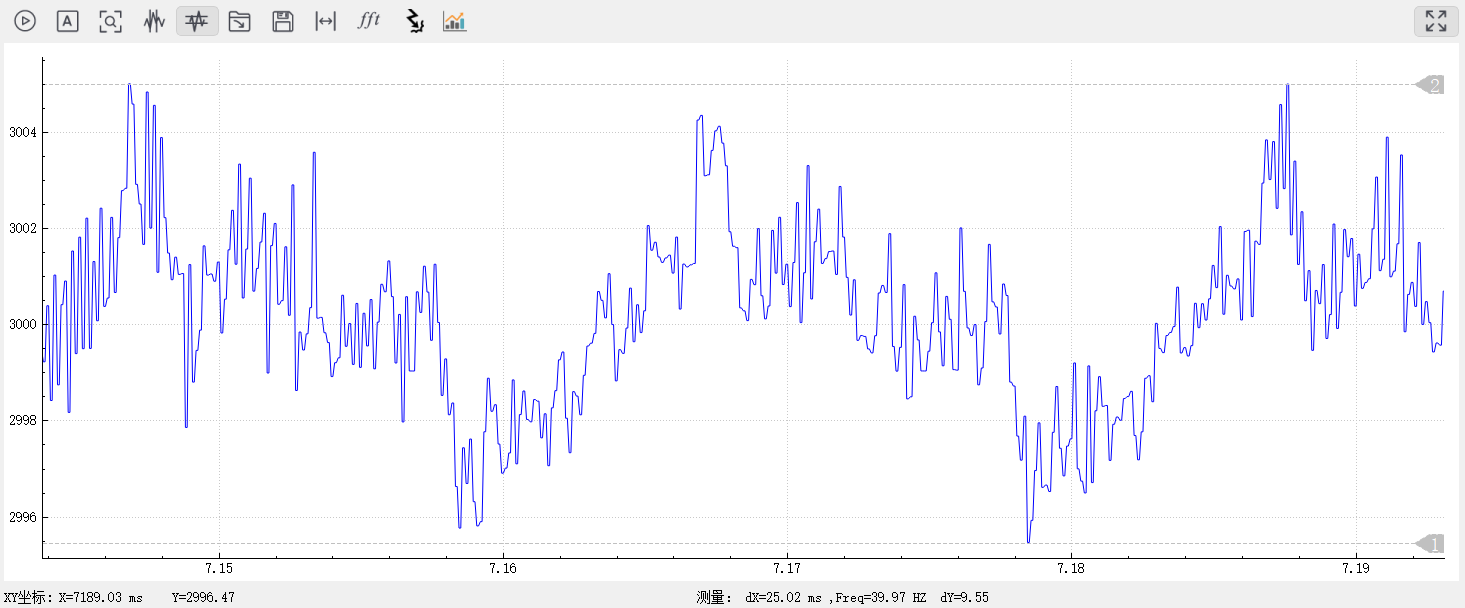

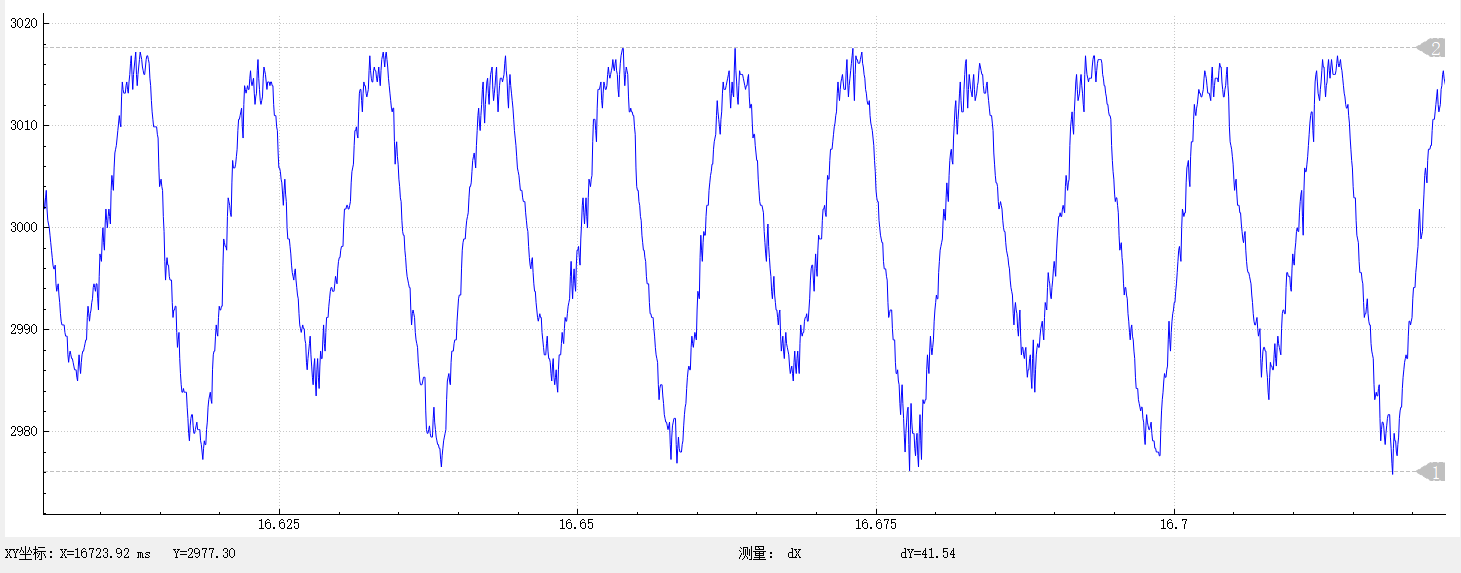

On the same set of general servo system with 23 bit optical encoder, we compared the speed fluctuation performance of optical encoder and MT6835 (after self calibration) in their closed-loop operation.

*The speed fluctuation data here comes from the host computer software of the servo system

Ø Operation effect of 23 bit optical encoder (3000RPM)

Note: This data is obtained by using a commercially available servo system (coded as a 23 bit optical encoder)

Ø Operation effect of MT6835 (3000RPM)

Note: This data is obtained by using the same commercial servo system (replace the 23 bit optical encoder with MT6835)

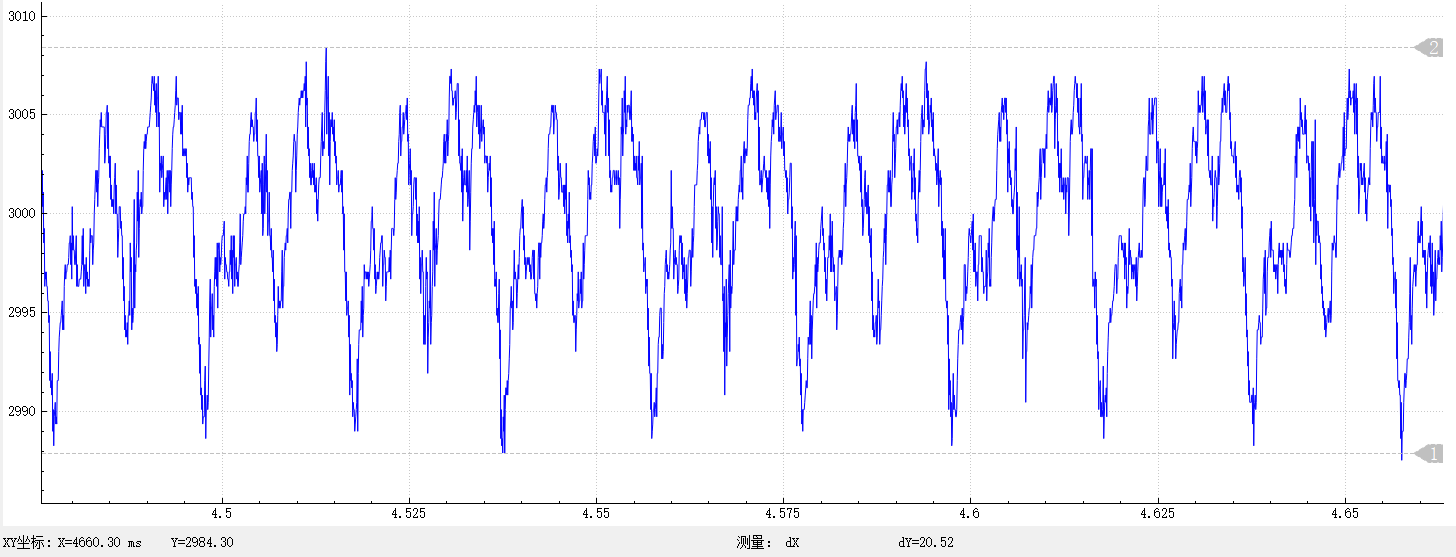

| Temperature compensation

Figure 1: The speed fluctuation of MT6835GT (without temperature compensation) is about ± 20.77 (rpm) under the condition of closed loop operation of 3000 RPM at 70 ℃

Figure 2: The speed fluctuation of MT6835GT (after temperature compensation) is about ± 10.26 (rpm) under the condition of closed loop operation of 3000 RPM at 70 ℃

The MT6835 has built-in temperature compensation, which can effectively suppress the deterioration of angle accuracy caused by temperature changes and the resulting large fluctuation of system speed.

| Dynamic response

On the same set of general servo system with 23 bit optical encoder, we compare the dynamic response of optical encoder and MT6835 (after self calibration) in their closed-loop operation

*The speed data here comes from the host computer software of the servo system

Closed loop 0~3000RPM rapid acceleration step response: 23 bit optical encoder (left figure) vs MT6835 (right figure)

MT6835 How to Run Automatic Calibration Explanation Video

McGonagall is committed to continuous breakthrough and innovation in magnetic semiconductor sensing technology. Since the release of the first generation magnetic encoder IC, it has experienced five years of market experience. The release of the fourth generation magnetic angle encoder IC-MT6835 will be a new starting point for the next five years in the development stage of Mageon's magnetic angle encoder IC. We will overcome difficulties and ride the waves on the way to tackle key core technologies in the spirit of "sharpening a sword in ten years"!